If you’ve ever stayed in a luxury hotel, you probably noticed that the bed sheets feel exceptionally soft, smooth, and inviting — while in many ordinary hotels, the sheets may feel a bit stiffer. For hotel owners and purchasing managers, understanding these differences is important when sourcing bedding sets that will enhance guest comfort and satisfaction.

As a hotel bedding manufacturer with over 20 years of experience, we’ve supplied a wide range of bed linens to properties from budget hotels to five-star resorts. In this guide, we’ll explain:

- The materials used in luxury hotel sheets

- Why fabric quality affects softness and durability

- How different hotels choose bedding based on their needs

- Customization options available for hotel buyers

1. The Secret Behind Luxury Hotel Softness: Materials and Weave

The softness of luxury hotel sheets comes down to fiber quality, thread count, and weaving method.

Common Materials Used in Hotels:

| Material | Characteristics | Typical Use in Hotels |

|---|---|---|

| 100% Cotton (Long-Staple Cotton, Egyptian Cotton, or Pima Cotton) | Soft, breathable, durable; long fibers create smoother fabric | 4–5 star hotels, premium suites |

| Cotton-Polyester Blend (e.g., 60% cotton, 40% polyester) | More wrinkle-resistant, cost-effective, slightly less soft | Mid-range hotels, business hotels |

| Microfiber | Soft, lightweight, quick-drying, budget-friendly | Budget hotels, short-stay inns |

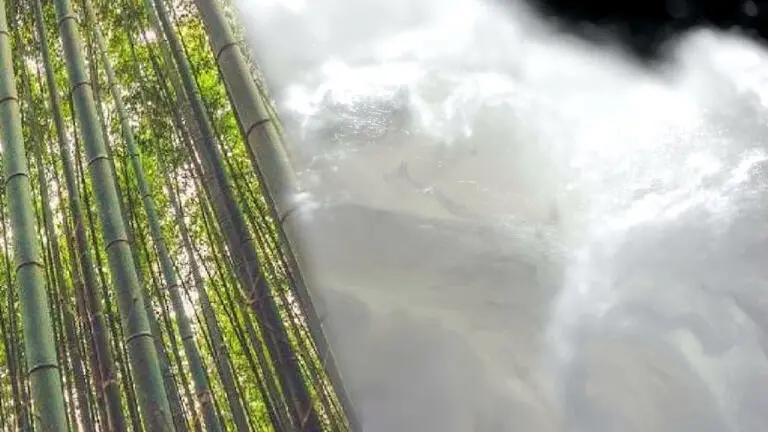

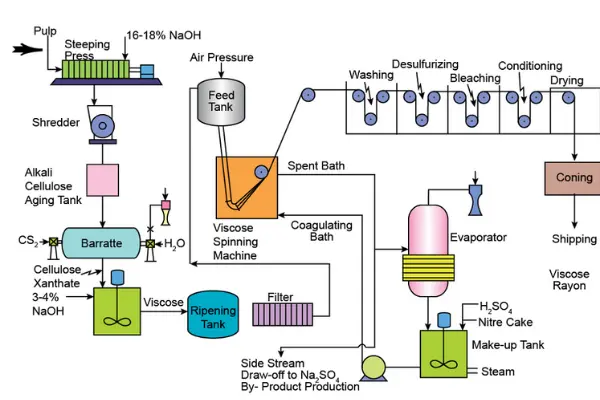

| Bamboo Fiber or Tencel | Naturally soft, eco-friendly, moisture-wicking | Boutique and eco-friendly hotels |

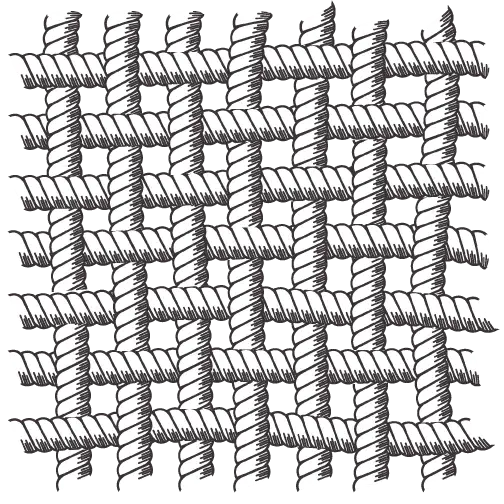

Weave Types That Affect Comfort:

- Sateen Weave – Smooth, silky feel, slight sheen (common in luxury hotels).

- Percale Weave – Crisp, cool, matte finish (favored in warm climates).

- Jacquard or Damask – Decorative patterns woven in, used for a more upscale look.

2. Why Budget Hotel Sheets Feel Stiffer

In ordinary hotels, the sheets often use:

- Short-staple cotton or higher polyester content for lower cost and durability under heavy washing.

- Lower thread count (120–200) for cost savings, but this also makes them feel rougher.

- Heavy starching during laundry for a crisp look, which can make the fabric feel hard.

Luxury hotels, in contrast, invest in:

- Long-staple cotton with higher thread counts (300–600), which feels smoother against the skin.

- Gentler laundry processes that avoid excessive starch and preserve fabric softness.

3. Choosing Bedding Based on Hotel Type

When we supply hotels, the selection often depends on:

- Budget hotels: Focus on easy maintenance, high washing durability, quick drying — usually cotton-polyester blends or microfiber.

- Mid-range hotels: Aim for a balance between comfort and cost — often use 100% cotton percale for a crisp, fresh feel.

- Luxury hotels & resorts: Prioritize guest experience with premium Egyptian cotton sateen, 400–600 thread count, and tailored finishes.

4. Customization Options for Hotel Buyers

As a manufacturer, we can customize hotel bedding sets to match your brand’s style and comfort standards:

- Fabric & Material: 100% cotton, cotton blend, microfiber, bamboo, or Tencel.

- Thread Count: 200–800 depending on comfort level and budget.

- Weave Style: Percale, sateen, jacquard, or custom patterns.

- Size & Fit: Standard, deep pocket, oversized king/queen.

- Branding: Embroidered hotel logos, woven labels, or custom color piping.

- Color & Design: Classic white, pastel tones, or bespoke designs.

5. Final Thoughts for Hotel Purchasing Managers

The bedding you choose directly impacts your guests’ sleep experience — and their overall impression of your hotel. Investing in higher-quality fabrics not only improves comfort but also extends the lifespan of your linens, making them a better long-term value.

As a direct manufacturer, we can help you select or design the perfect bedding set for your hotel — whether you’re outfitting a luxury resort, a cozy boutique inn, or a large business hotel chain.

Contact us today to explore material samples, thread count options, and customized hotel bedding solutions.