Quality Control

At Hangzhou Yintex Co., Ltd., we are committed to producing high-quality, safe, and sustainable textile products. To ensure our customers receive the best, our products and manufacturing processes comply with internationally recognized standards. We hold the following certifications: BSCI, OEKO-TEX Standard 100, GRS (Global Recycled Standard), and OEKO-TEX STeP. These certifications reflect our dedication to ethical sourcing, product safety, environmental sustainability, and social responsibility.

Certificates

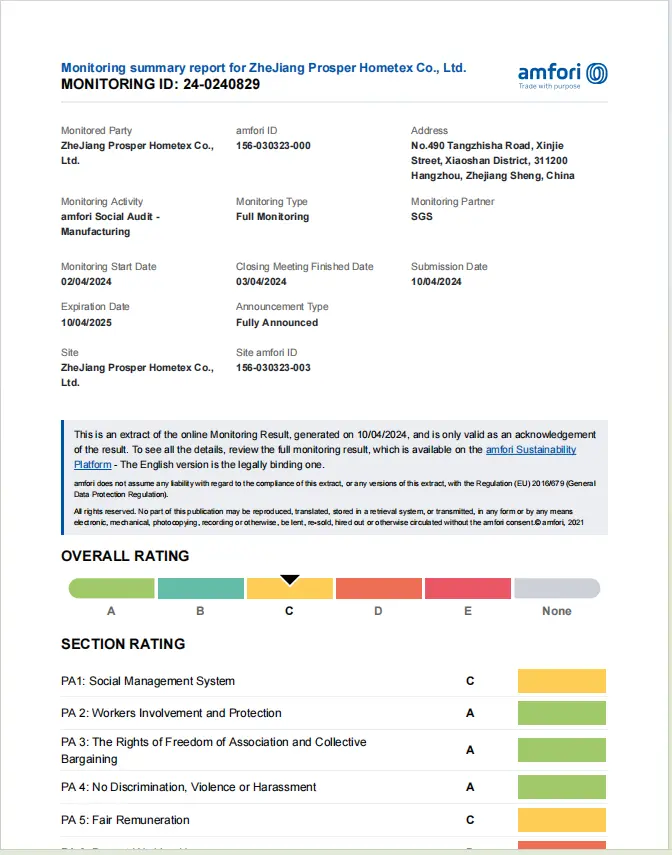

1. BSCI – Business Social Compliance Initiative

The BSCI (Business Social Compliance Initiative) is a leading monitoring system that promotes fair labor practices and ethical working conditions in global supply chains. Managed by “amfori,” a European trade organization, BSCI ensures that our company adheres to international labor standards, including:

- No child labor or forced labor

- Fair wages and working hours

- Occupational health and safety compliance

- Freedom of association and non-discrimination

- Ongoing audits and improvement programs

Although BSCI is not a traditional certification, it demonstrates our commitment to continuous social compliance improvements, ensuring a responsible and transparent supply chain.

2. OEKO-TEX Standard 100 – Certified Safe Textiles

The OEKO-TEX Standard 100 is a globally recognized certification that guarantees our textile products are free from harmful substances. This certification means that every component of our products (fabric, threads, buttons, prints, etc.) has been tested for harmful chemicals, ensuring safety for consumers.

Key Aspects:

- Tests for over 100 regulated and non-regulated substances, including heavy metals, pesticides, formaldehyde, and allergenic dyes.

- Four product classes based on skin contact intensity:

- Class I: Baby products (most stringent requirements)

- Class II: Products in direct skin contact (e.g., clothing, bedding)

- Class III: Outerwear

- Class IV: Home textiles (e.g., curtains, upholstery)

- Annual renewal with updated testing criteria to meet the latest safety standards.

By obtaining OEKO-TEX Standard 100 certification, we assure our customers that our products are safe, skin-friendly, and free from hazardous substances.

3. GRS – Global Recycled Standard

Sustainability is at the core of our operations. Our GRS (Global Recycled Standard) certification ensures that our products contain verified recycled materials and meet strict environmental and social criteria throughout the supply chain.

What GRS Covers:

- Recycled Content: A minimum of 20% recycled materials is required, with higher percentages (50% or 100%) allowing specific product claims.

- Environmental Impact: Ensures sustainable resource use, water and energy efficiency, and strict chemical restrictions.

- Social Responsibility: Follows International Labour Organization (ILO) standards, promoting ethical work conditions and fair wages.

- Supply Chain Transparency: Audits and tracking systems ensure traceability from raw materials to the finished product.

This certification reassures our customers that our products contribute to the circular economy, reducing environmental impact while maintaining high-quality standards.

4. OEKO-TEX STeP – Sustainable Textile & Leather Production

Beyond individual product safety, our manufacturing facilities hold OEKO-TEX STeP certification, a sustainability-focused certification that evaluates the entire production process.

Key Evaluation Areas:

- Chemical Management: Safe handling and elimination of hazardous substances.

- Environmental Performance: Sustainable energy and water consumption, waste management, and emissions control.

- Social Responsibility: Ensures ethical labor practices and fair working conditions.

- Health & Safety: Workplace safety and worker well-being.

- Quality Management: Continuous process improvements and compliance tracking.

STeP certification reflects our holistic approach to responsible production, making sure our entire supply chain aligns with sustainability goals.

Our Commitment to Quality and Sustainability

At Hangzhou Yintex Co., Ltd., we take pride in ensuring that our products meet the highest safety, ethical, and environmental standards. Our certifications demonstrate our dedication to responsible sourcing, sustainable manufacturing, and customer safety. When you choose our products, you can trust that they are safe, eco-friendly, and ethically produced.

For more details about our certified products or to discuss your specific requirements, feel free to contact us!

Quality Control Management System

At Hangzhou Yintex Co., Ltd., we prioritize strict quality control to ensure our comforters, pillows, bed sheet sets, and mattress toppers meet international standards such as GRS, OEKO-TEX, EN, ISO, and ASTM. Our comprehensive Quality Control Management System (QCMS) covers every stage of production, from raw material selection to finished product inspection, ensuring superior durability, safety, and performance.

Why Choose Our Quality Control System?

✔ Rigorous Material Testing: We enforce AQL 2.5 sampling inspection and conduct tests for thread count, fill power, tensile strength, and flame retardancy (BS7175, OEKO-TEX).

✔ Advanced Manufacturing Control: We use laser cutting, Datacolor spectrophotometers, ultrasonic sealing, and precision weighing systems for consistency.

✔ Strict Product Inspections: Our AQL 1.0 final inspection ensures dimensional accuracy (±1.5 cm), colorfastness (Grade ≥4), and pilling resistance (Grade ≥3-4).

✔ Packaging & Logistics Control: We use moisture-proof packaging, compression recovery tests, and temperature monitoring to maintain product integrity during transit.

✔ Full Traceability & Continuous Improvement: Our 5-level traceability code, batch retention policies, and data-driven quality analytics guarantee fast issue resolution and continuous process enhancements.

Ensuring Premium Quality with Smart Technology

Our Digital Quality Management System (QMS) integrates real-time SPC monitoring, automated alerts, and AI-driven defect detection to maintain 98% first-pass inspection rates and a ≤0.8% rework rate. By investing in quarterly process optimizations and annual equipment upgrades, we deliver high-quality home textiles that exceed customer expectations.y and efficiency.