Synthetic fibers are man-made textile materials created through chemical processes, primarily derived from petrochemicals. Unlike natural fibers like cotton or wool, synthetic fibers are engineered for specific performance, including durability, elasticity, moisture resistance, and cost-efficiency.

In this article, we explore what synthetic fibers are made of, how they’re produced, and why they remain essential across apparel, bedding, and industrial applications.

The Core Composition of Synthetic Fibers

Most synthetic fibers are made from polymers—long chains of repeating molecular units—typically derived from crude oil, natural gas, or coal. These polymers are processed through polymerization, forming the base material that can be spun into fibers.

Common chemical building blocks include:

- Petroleum-based compounds, such as ethylene, benzene, and toluene

- Monomers, like terephthalic acid, adipic acid, and ethylene glycol

- Plastic precursors, like polyester (PET), nylon (PA), or acrylic (PAN)

How Are Synthetic Fibers Made?

The manufacturing process generally follows these steps:

1. Polymerization

Monomers are chemically reacted to form polymers. For example, in polyester production:

- Terephthalic acid + ethylene glycol → polyethylene terephthalate (PET)

2. Extrusion (Spinning)

Molten polymer is forced through a spinneret (a metal plate with holes) to form filaments.

3. Cooling & Solidifying

Filaments are cooled, stretched, and solidified to improve strength and flexibility.

4. Texturizing & Finishing

Fibers may be crimped, dyed, or coated to alter hand feel, luster, or performance (e.g., moisture-wicking or flame resistance).

This process results in continuous filament fibers or staple fibers, depending on the application.

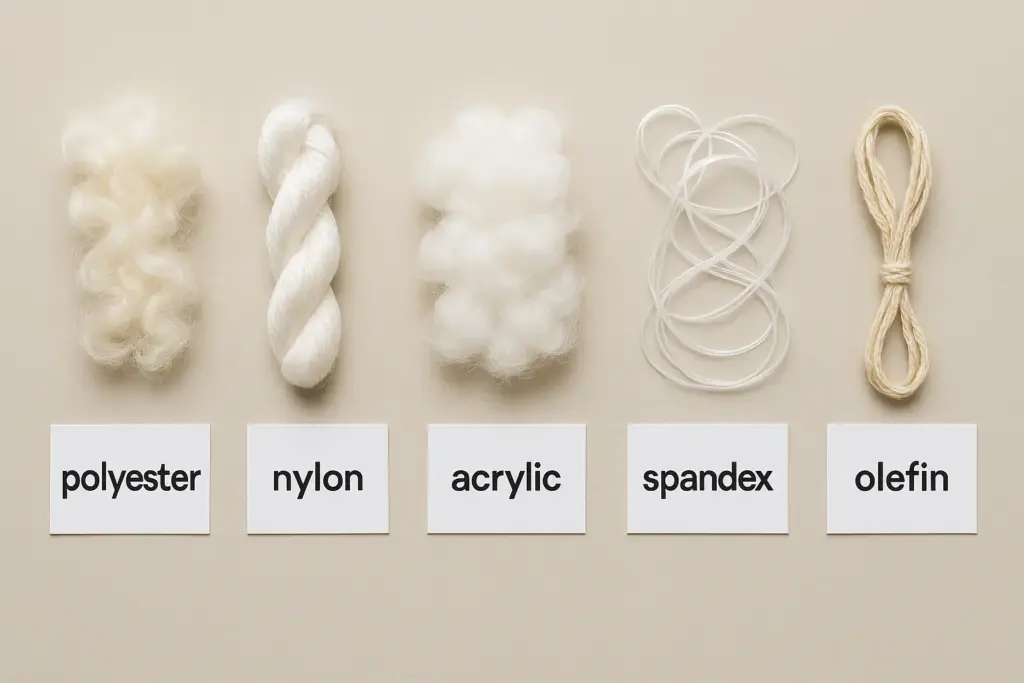

Major Types of Synthetic Fibers and Their Ingredients

| Fiber Type | Primary Ingredients | Key Properties |

|---|---|---|

| Polyester | Ethylene glycol + terephthalic acid (PET) | Durable, quick-drying, wrinkle-resistant |

| Nylon (Polyamide) | Adipic acid + hexamethylene diamine | Elastic, abrasion-resistant, smooth |

| Acrylic | Acrylonitrile (derived from propylene) | Soft, wool-like, warm, fade-resistant |

| Spandex (Elastane) | Polyurethane-based monomers | Extremely elastic, shape-retaining |

| Olefin (Polypropylene) | Propylene gas | Lightweight, water-repellent, cheap |

Synthetic vs Natural Fiber: Key Differences

| Aspect | Synthetic Fibers | Natural Fibers |

|---|---|---|

| Source | Petrochemical or chemically modified plant-based | Plants or animals (cotton, wool, silk) |

| Durability | Highly durable, less biodegradable | Biodegradable, but wears faster |

| Moisture Management | Often moisture-wicking or hydrophobic | Absorbent, breathable |

| Environmental Impact | Higher carbon footprint; recyclable variants exist | Lower footprint; but requires land/water |

Modern innovations like recycled polyester (rPET) or bio-based synthetics are helping reduce the environmental impact of synthetic fibers.

Applications Across Industries

Synthetic fibers are valued for their versatility, low cost, and consistent quality. They dominate many sectors:

▸ Apparel

Activewear, swimwear, outerwear, socks, and stretch fabrics (with spandex)

▸ Home Textiles

Duvets, pillows, mattress pads, curtains, and microfiber sheets

▸ Industrial Use

Carpeting, upholstery, seatbelts, filtration fabrics, ropes, and geotextiles

▸ Medical and Hygiene

Surgical gowns, face masks, sanitary wipes, disposable linens

Environmental Considerations

While synthetic fibers offer performance and price benefits, they raise concerns such as:

- Microplastic shedding in laundry

- Non-biodegradability in landfills

- Fossil fuel dependency

Sustainable alternatives include:

- rPET (Recycled Polyester)

- PLA (Polylactic Acid) from cornstarch

- Biodegradable polyamides

For eco-conscious brands, sourcing certified recycled synthetic fibers and using closed-loop dyeing processes can reduce environmental impact.

Conclusion

Synthetic fibers are engineered from petroleum-based polymers and serve as essential materials across industries due to their strength, affordability, and versatility. While traditionally made from fossil fuels, innovations in recycled content and green chemistry are driving the evolution toward more sustainable synthetic textiles.

Understanding what synthetic fibers are made of is critical for manufacturers, designers, and procurement specialists seeking to align product performance with environmental responsibility.

Leave a Reply