In healthcare environments, fitted sheets for hospital beds play a critical role in ensuring patient comfort, hygiene, and operational efficiency. Unlike standard bed linens, hospital bed sheets must accommodate adjustable bed frames, withstand frequent laundering, and meet strict durability and safety requirements.

This guide outlines the essential features, material options, and B2B sourcing considerations for fitted hospital bed sheets.

Why Fitted Sheets Are Essential in Medical Settings

Fitted sheets are designed with elasticized corners that secure tightly around the mattress, preventing bunching, shifting, or wrinkling—especially critical in hospital beds where patients are repositioned frequently or use articulated bed bases.

Core benefits include:

- Prevents sheet slippage and patient discomfort

- Improves infection control through a smooth, sealed surface

- Allows for faster bed turnover in high-traffic healthcare facilities

- Enhances overall patient hygiene and safety

Key Features of Hospital Bed Fitted Sheets

To meet the unique demands of clinical environments, hospital bed fitted sheets require:

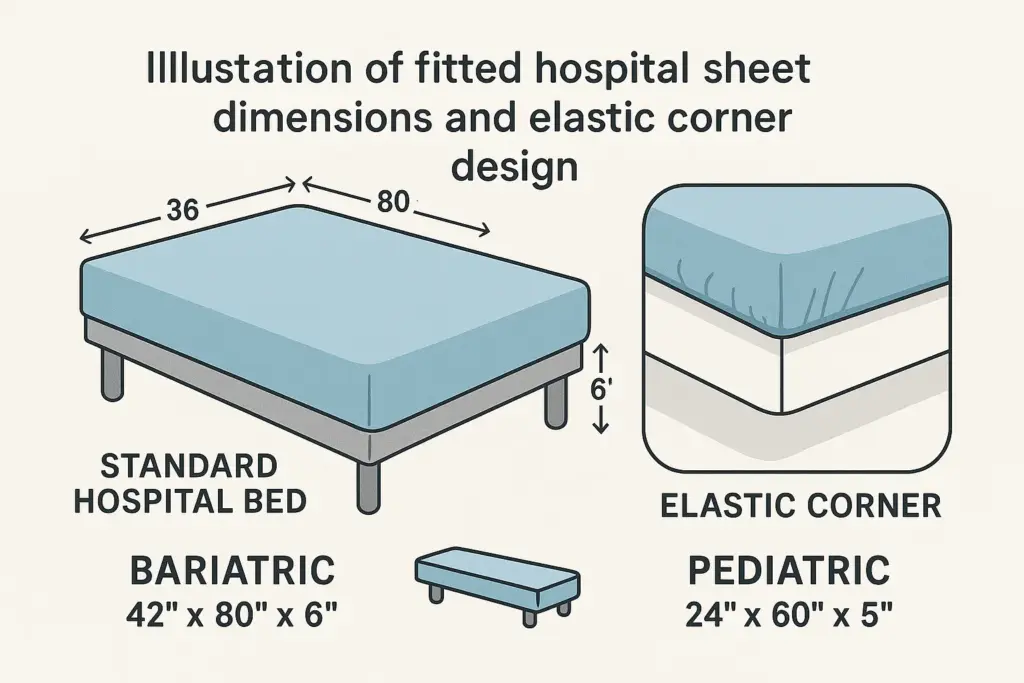

1. Precise Sizing

- Standard hospital mattress size: 36″ x 80″ x 6″–9″

- Bariatric and pediatric sizes also available

- Deep-pocket or stretch-knit versions for adjustable bed movements

B2B Tip: Offer multiple size options with color-coded tags for faster inventory sorting.

2. Durable, Medical-Grade Fabric

- Cotton-polyester blends (50/50 or 60/40) for durability + breathability

- 100% cotton for high-comfort environments (private clinics, recovery rooms)

- Knitted polyester jersey for stretchable, wrinkle-resistant performance

Must withstand high-temperature laundering (≥71°C / 160°F) and industrial wash cycles.

3. Anti-Pilling & Low-Lint Finish

Pilling or linting can cause discomfort and reduce hygiene. Industrial-grade sheets should be:

- Smooth and abrasion-resistant

- Double-stitched at seams for durability

- Treated with softeners or anti-lint finishes

4. Color Options and Labeling

- White is standard for most medical facilities

- Color-coded or hem-tagged options help distinguish sheet sizes or hospital departments

- Bleach-safe dyeing options for colored institutional use

Common Materials Used

| Material | Advantages | Best For |

|---|---|---|

| Cotton-Poly Blend (T-180/T-200) | Cost-effective, durable, fast drying | General hospitals, large-scale use |

| 100% Cotton Percale | Soft, breathable, hypoallergenic | Maternity wards, private rooms |

| Polyester Knit Jersey | Stretch fit, wrinkle-resistant, moisture-wicking | Rehabilitation centers, adjustable beds |

| Fluid-Resistant Coated Fabric | Prevents fluid penetration, easy clean | ICU, surgical recovery |

Fitted Sheets for Specialized Hospital Beds

▸ Adjustable Beds

Require extra flexibility and deeper pockets. Knit jersey fabrics or elasticized panels are often used.

▸ Bariatric Beds

Larger and wider sheet sizes (up to 42″ or 48″) with reinforced seams for heavy-duty use.

▸ Pediatric Beds

Smaller dimensions with gentle fabrics; often OEKO-TEX® or GOTS certified.

▸ Pressure-Relief Mattresses

Sheets must stretch and recover with mattress contour changes. Look for 4-way stretch sheets.

B2B Sourcing Considerations

For hospitals, nursing homes, or healthcare product distributors, choosing the right supplier involves:

- ✅ Bulk availability with low MOQ

- ✅ Private label/OEM printing or packaging

- ✅ Compliance with medical hygiene standards (e.g., ISO 13485, OEKO-TEX)

- ✅ Fast lead time with consistent sizing

- ✅ Shrink-resistance after repeated washing

Also consider drop-shipping partnerships for long-term care homes or home healthcare platforms.

Conclusion

Fitted sheets for hospital beds are not just a comfort product—they’re a functional, hygienic, and operational necessity. Whether for general hospital use or specialized medical settings, the right sheet enhances both patient care and institutional efficiency. For B2B buyers, offering durable, customizable, and compliant fitted sheets is a must in today’s healthcare textile market.

Leave a Reply