If you’ve ever bought two sets of 100% cotton bed sheets and noticed that one feels luxuriously soft while the other feels stiff or coarse, you’re not alone. While both claim to be “100% cotton,” softness can vary significantly depending on several key factors. In this article, we’ll break down the reasons behind the differences in softness and what you should look for when shopping for cotton sheets.

1. Type of Cotton Fiber Used

Not all cotton is created equal. The length and quality of the cotton fiber (called “staple”) greatly affect softness.

- Short-Staple Cotton: Typically used in lower-end sheets. Short fibers make the fabric less smooth and more prone to pilling.

- Long-Staple Cotton: Offers better softness, durability, and strength. Examples include:

- Egyptian cotton

- Pima cotton (including Supima®)

- Indian long-staple cotton

Sheets made from long-staple cotton are noticeably smoother and softer to the touch.

2. Weave Type

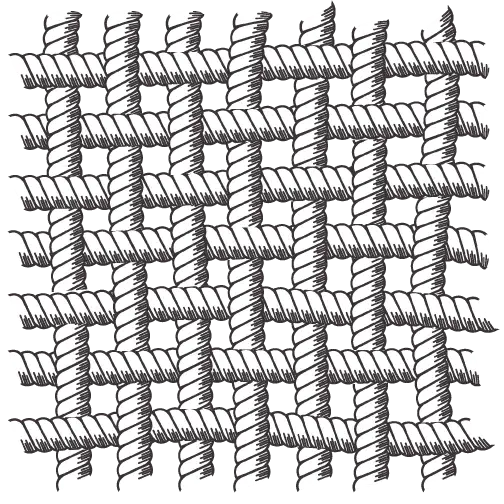

The weaving pattern plays a huge role in the feel of cotton sheets.

- Percale Weave: A plain weave with a matte finish and a cool, crisp feel.

- Sateen Weave: A satin-like weave with a silky smooth finish and more sheen. Sateen sheets usually feel softer out of the box.

If you prefer buttery-soft sheets, go for sateen. For hotel-like crispness, choose percale.

3. Thread Count

Thread count refers to the number of threads woven per square inch. But higher isn’t always better.

- 200–400 TC: Ideal range for breathability and softness.

- Above 400 TC: Can be softer but sometimes achieved by using multi-ply threads, which may feel heavier or trap heat.

Quality matters more than just thread count. A 300 TC long-staple cotton sheet can be much softer than a 600 TC short-staple one.

4. Yarn and Finishing Process

Even with the same cotton and weave, finishing techniques affect softness:

- Combed Cotton: Short fibers are removed, leaving smoother, softer yarn.

- Mercerization: A chemical process that adds luster and improves dye retention and softness.

- Enzyme-Washed / Stone-Washed Cotton: Pre-washing processes used to break in the fabric for extra softness.

Sheets labeled “pre-washed,” “enzyme-washed,” or “combed cotton” are typically softer right out of the package.

5. Fabric Weight (GSM)

Grams per square meter (GSM) is more common in towels, but it can also be used in bedding to describe thickness and density.

- Lightweight (100–140 GSM): Airy, crisp feel.

- Medium (140–170 GSM): Balanced feel, soft and breathable.

- Heavy (170+ GSM): Thicker, warmer, and often softer if high-quality yarn is used.

A higher GSM doesn’t always mean better, but a medium GSM with high-quality yarn usually feels great.

Conclusion: What Makes Cotton Sheets Truly Soft?

To summarize, here are the main reasons why some 100% cotton sheets feel softer than others:

| Factor | Better for Softness? |

|---|---|

| Fiber Type | Long-staple cotton (e.g., Egyptian, Pima) |

| Weave | Sateen (silky), Percale (crisp but softens over time) |

| Thread Count | Ideal between 200–400 with single-ply yarn |

| Finishing | Combed, enzyme-washed, or mercerized |

| GSM | Medium (140–170 GSM) for softness + breathability |

So next time you shop for cotton bed sheets, don’t be swayed by the “100% cotton” label alone. Look deeper into the fabric specs and finishing processes to choose sheets that truly offer the softness you crave.

Leave a Reply