Woven fabric is one of the most fundamental and widely used textile structures across industries—from fashion to home furnishings, automotive interiors to industrial filters. Recognized for its dimensional stability, versatility, and design flexibility, woven fabric plays a central role in the global textile supply chain.

In this article, we break down what woven fabric is, how it’s made, its key classifications, and where it’s used across commercial and consumer applications.

What Is Woven Fabric?

Woven fabric is a textile produced by interlacing two sets of yarns at right angles: the warp (lengthwise) and the weft (crosswise), typically on a loom. The resulting structure has uniform strength, stability, and low stretch, especially compared to knits or nonwovens.

This basic interlacing system allows for countless variations in patterns, densities, textures, and finishes—making woven fabrics both functional and decorative.

Characteristics of Woven Fabric

| Feature | Description |

|---|---|

| Structure | Interlaced yarns (warp and weft) at 90° angles |

| Stretch | Minimal; generally non-stretch unless blended with elastane |

| Durability | High tensile strength and abrasion resistance |

| Drape | Varies based on fiber and weave type (from stiff canvas to flowing chiffon) |

| Breathability | Customizable through yarn count and weave density |

| Edge Behavior | Prone to fraying unless hemmed or treated |

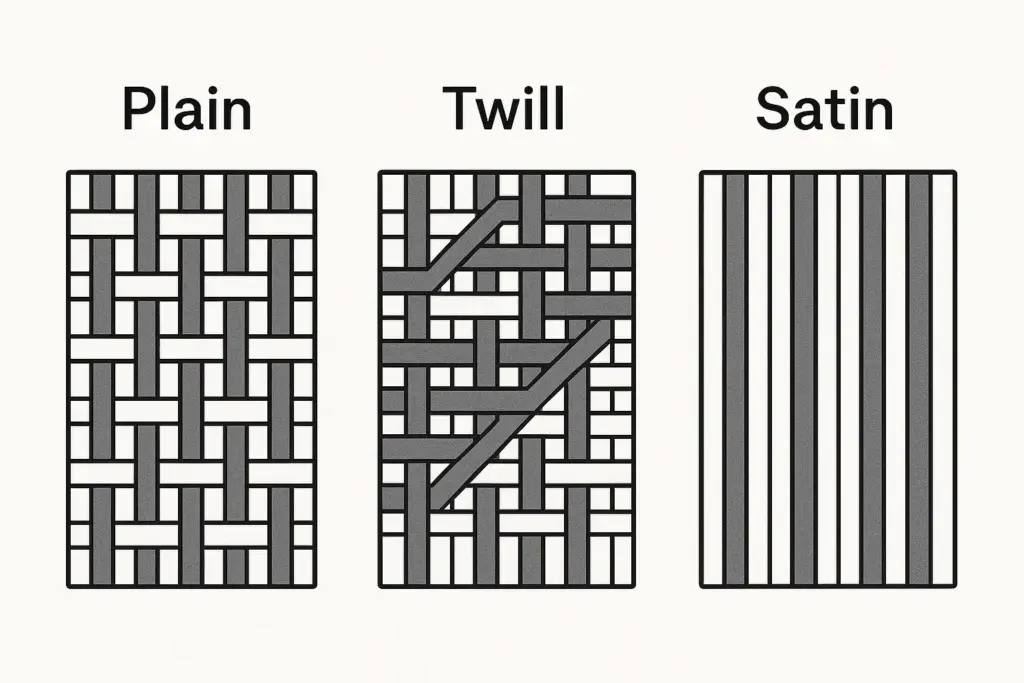

Common Types of Woven Fabric

| Type | Weave Pattern | Common Use Cases |

|---|---|---|

| Plain Weave | 1-over-1-under | Poplin, muslin, voile, cretonne |

| Twill Weave | Diagonal ribs | Denim, gabardine, chino, mattress ticking |

| Satin Weave | Floating yarns | Satin, sateen—used in luxury bedding and apparel |

| Jacquard Weave | Complex patterns | Decorative upholstery, curtains, brocades |

| Leno Weave | Open mesh | Sheer curtains, mosquito netting |

Woven vs. Knit vs. Nonwoven: What’s the Difference?

| Property | Woven Fabric | Knit Fabric | Nonwoven Fabric |

|---|---|---|---|

| Structure | Interlaced yarns | Interlooped yarns | Bonded fibers (not woven) |

| Stretch | Low | High | Varies |

| Drape | Moderate | Flexible | Stiff to soft |

| Common Uses | Apparel, bedding | Activewear, tees | Medical masks, filters |

| Durability | High | Medium | Often single-use |

Industrial and Commercial Applications

Woven fabrics are essential across industries:

- Home Textiles: Sheets, pillowcases, curtains, upholstery

- Apparel: Shirts, trousers, jackets, uniforms

- Hospitality: Bed linens, tablecloths, drapery fabrics

- Healthcare: Bandages, gowns, scrubs (when made with blends)

- Technical Textiles: Geotextiles, filtration media, airbags

- Automotive: Seat covers, trunk liners, sound insulation layers

Their dimensional integrity and design versatility make them a preferred choice in mass customization and high-durability product lines.

Why Choose Woven Fabric?

- ✅ High dimensional stability for precise sizing

- ✅ Diverse aesthetics from simple to ornate weaves

- ✅ Long-term wear performance

- ✅ Applicable to natural, synthetic, and blended yarns

- ✅ Supports complex finishes (coating, printing, brushing, etc.)

Conclusion

Woven fabric is not just a material—it’s a structural technology that defines the backbone of modern textiles. Whether you’re sourcing fabrics for hospitality bedding, technical gear, or premium fashion, understanding woven fabric types and properties can empower smarter sourcing, design, and end-use decisions.

Leave a Reply