Pilling is one of the most common — and frustrating — issues in the textile industry. Whether it’s high-thread-count bed sheets or cozy knit blankets, pilling can compromise product appearance, tactile experience, and brand reputation.

In B2B markets such as hospitality, healthcare, and retail, where textile quality directly impacts customer satisfaction, understanding and managing pilling is essential for quality assurance and long-term value.

What Is Pilling?

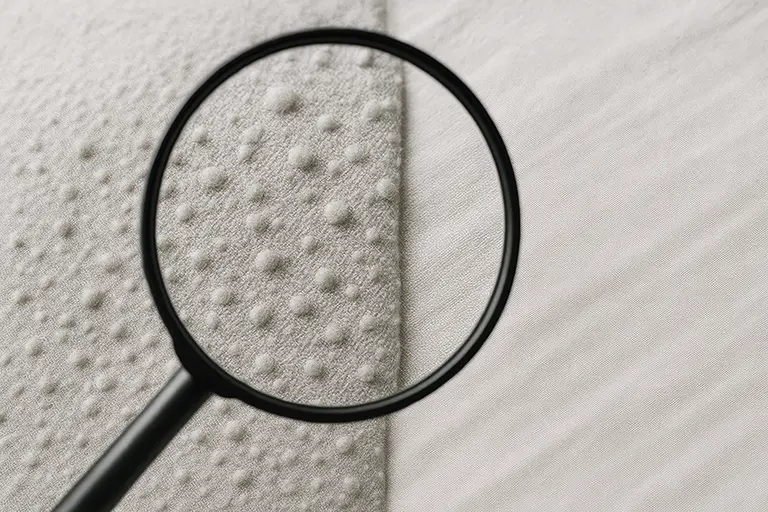

Pilling refers to the formation of small, fuzzy balls of fiber — commonly called “pills” — on the surface of a fabric. These pills are typically caused by friction or abrasion during use or laundering, which causes loose fibers to entangle and form visible lumps.

Pilling is most noticeable on soft surfaces like bedding, upholstery, and clothing, particularly in areas exposed to repeated rubbing, such as pillowcases, fitted sheets, or frequently sat-on cushions.

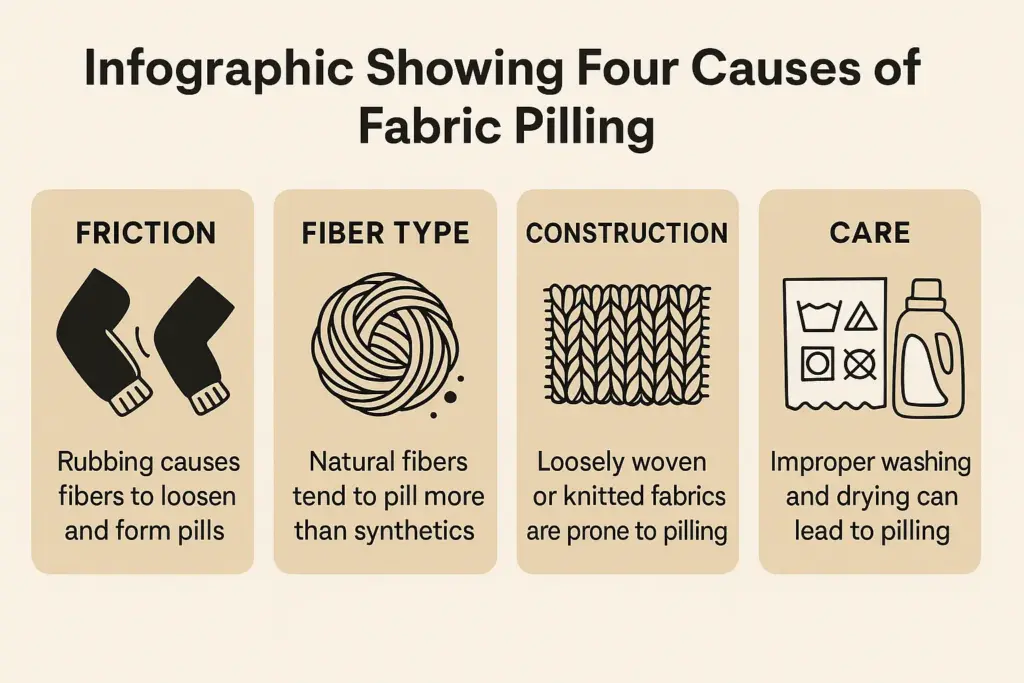

What Causes Pilling?

Several factors contribute to pilling:

1. Friction & Movement

- Rubbing against skin, furniture, or other fabrics

- Repeated laundering or tumble drying

2. Fiber Composition

- Short-staple fibers (e.g., carded cotton, wool) are more prone to breakage and tangling

- Synthetic fibers (like polyester) are stronger and less likely to shed but hold onto pills longer

3. Fabric Construction

- Loosely woven or knitted fabrics pill more than tightly woven ones

- Brushed or textured surfaces (like flannel or fleece) have more raised fibers that can pill

4. Washing and Care Methods

- Aggressive washing cycles or high heat can worsen pilling

- Mixing rough items (like jeans or towels) with delicate items in the same load

How Is Pilling Measured?

In professional textile labs, pilling resistance is tested using standardized methods such as:

- Martindale Abrasion Tester (ISO 12945-2)

- Random Tumble Pilling Tester (ASTM D3512)

- ICI Pilling Box Method

Results are typically graded from 1 (severe pilling) to 5 (no pilling). Many hospitality and retail brands require a minimum grade of 3–4 after specific wash cycles.

How to Prevent or Reduce Pilling

✅ 1. Choose Long-Staple Fibers

Longer cotton fibers (e.g., long staple or extra-long staple) reduce loose ends and minimize pilling. Egyptian cotton and Supima® are top choices in this category.

✅ 2. Opt for Compact or Combed Yarns

These yarns are processed to remove short fibers, resulting in smoother and stronger fabrics.

✅ 3. Tightly Woven Fabrics

Percale or sateen weaves with a higher thread count reduce surface fuzz and wear.

✅ 4. Proper Finishing

Anti-pilling finishes or enzyme washes can reduce fiber shedding and extend fabric longevity.

✅ 5. Educate End Users

Recommend cold or gentle machine washing, low tumble drying, and separating delicate items from abrasive laundry.

Best Fabric Choices for Anti-Pilling Performance

| Fabric Type | Pilling Resistance | Notes |

|---|---|---|

| Combed Cotton | High | Ideal for high-use bedding |

| Tencel™ / Modal | High | Smooth surface, low fuzziness |

| Poly-cotton blends | Medium–High | Stable structure, may retain pills |

| Flannel / Fleece | Low | Naturally fuzzy; use anti-pilling treatments |

Why Pilling Prevention Matters in B2B

In business contexts, pilling isn’t just a cosmetic flaw — it’s a customer perception issue. For hotels, healthcare facilities, or online bedding brands, early or visible pilling can lead to:

- Negative product reviews

- Increased returns or replacements

- Loss of client confidence in quality

By investing in anti-pilling strategies at the product development and sourcing stage, businesses ensure longer-lasting textiles, better brand perception, and lower lifecycle costs.

Final Thoughts

Pilling may be a natural byproduct of fiber friction — but it’s not inevitable. With smart fiber selection, superior yarn processing, and responsible care instructions, pilling can be significantly minimized or even eliminated. For manufacturers and brands, this means more durable products and happier end users.

Leave a Reply